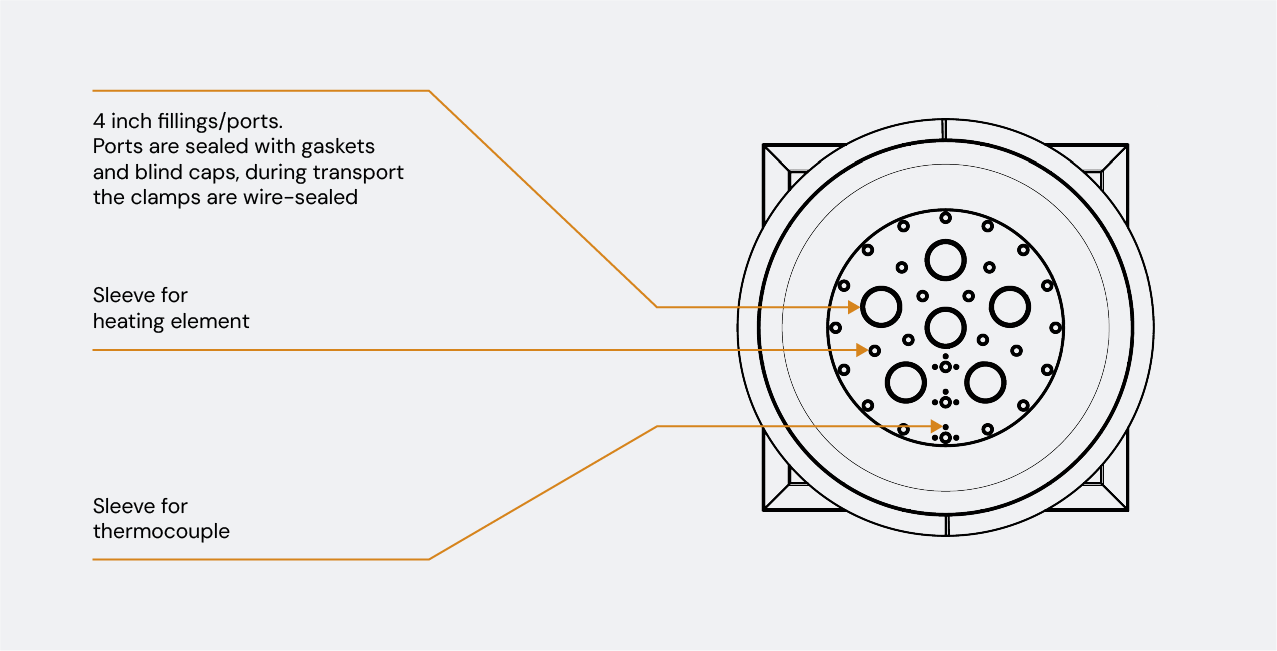

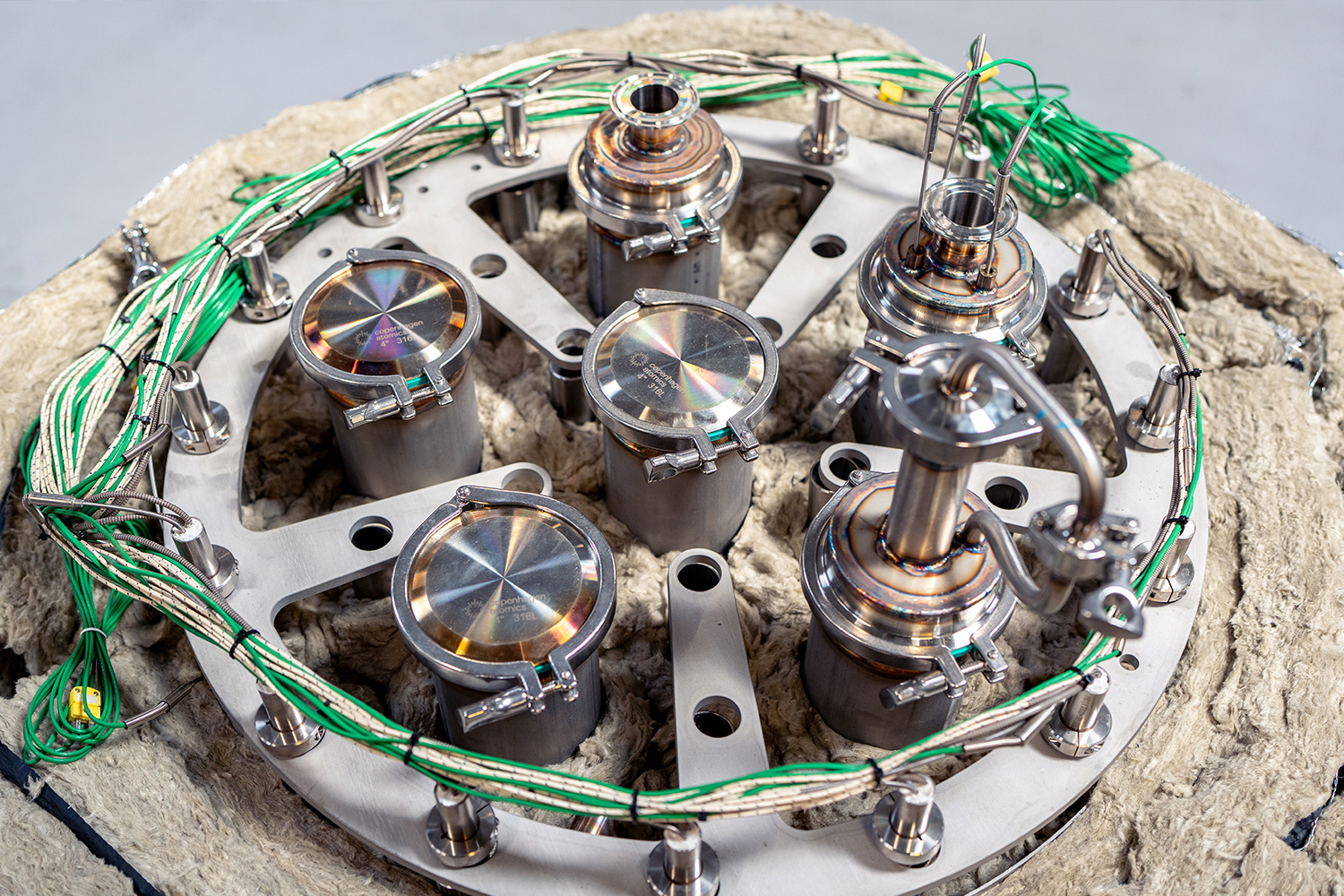

Salt tanks with a 1,000-liter capacity, built-in heaters, and a gas system

Efficient, high-temperature molten salt transport tanks with precise heat control, corrosion resistance, and seamless integration for industrial applications.

The Salt Tanks offer an ideal solution for the efficient storage and temperature regulation of molten salts. Engineered for durability, these tanks are constructed using 316 stainless steel to provide superior resistance to corrosion and high temperatures (up to 650℃).

Integrated sleeved heating elements ensure even heat distribution to prevent crystallization, while the dip tube design enables smooth salt transfer with minimal pressure.